Metal Casting: Reducing Weight Without Compromising Strength

Why Aluminum Factory Castings Support Better Warmth Dissipation in Industrial Systems

Light weight aluminum factory spreadings play an essential role in enhancing warmth dissipation within industrial systems. Their remarkable thermal conductivity permits efficient heat transfer, while their light-weight nature improves functional effectiveness. Furthermore, advanced casting strategies allow elaborate layouts that optimize thermal management. These qualities collectively contribute to better performance and power cost savings. Nevertheless, recognizing the full influence of these residential properties requires a more detailed assessment of their various applications and advantages in commercial setups.

Exceptional Thermal Conductivity of Aluminum

Light weight aluminum is renowned for its remarkable thermal conductivity, making it a favored material in numerous applications. This residential property makes it possible for light weight aluminum to efficiently move heat, which is vital in sectors that rely on efficient warmth administration. The high thermal conductivity of light weight aluminum allows it to dissipate warmth rapidly, decreasing the threat of overheating in systems such as engines, electronics, and warmth exchangers.

Additionally, light weight aluminum's thermal efficiency adds to enhanced performance and power cost savings in many commercial procedures. When utilized in factory castings, aluminum can be formed right into detailed forms that enhance warmth dissipation further. This capability is especially useful in applications calling for fast air conditioning or temperature level law.

Lightweight Nature of Light Weight Aluminum Castings

The light-weight nature of aluminum castings supplies considerable benefits throughout numerous markets, particularly in applications where lowering weight is necessary. This feature enhances operational efficiency, as lighter elements add to decrease energy consumption throughout transport and handling. In automobile manufacturing, as an example, the decrease in total automobile weight can cause improved gas effectiveness and enhanced efficiency. In a similar way, in aerospace applications, the reduction in weight is vital for attaining excellent trip efficiency and gas cost savings.

Enhanced Design Versatility for Warmth Management

Style versatility in warmth management is a vital characteristic of aluminum spreadings that allows engineers to optimize thermal performance in numerous applications. Aluminum Foundry. The adaptability of aluminum makes it possible for the production of intricate geometries and customized layouts, which are important for effective warmth dissipation. This adaptability assists in the integration of cooling channels, fins, and various other attributes that enhance thermal transfer in commercial systems

The ability to produce lightweight components without endangering structural honesty allows for cutting-edge designs that can effectively handle warm in constrained spaces. By leveraging sophisticated casting strategies, engineers can make improvements the thermal residential properties of light weight aluminum spreadings to satisfy particular operational needs. This level of customization not only boosts efficiency however also adds to energy efficiency, ultimately bring about minimized operational costs. In this way, light weight aluminum castings act as a substantial resource for markets looking for improved warmth monitoring remedies.

Resistance to Corrosion and Oxidation

Efficient heat administration is typically challenged by environmental factors, particularly corrosion and oxidation. Light weight aluminum factory castings exhibit superior resistance to these problems, making them an exceptional option for industrial systems. The natural development of a safety oxide layer on light weight aluminum surfaces helps protect against better degradation, guaranteeing the stability of components over time. This inherent resistance allows aluminum castings to maintain their thermal and architectural buildings also in harsh settings, where direct exposure to moisture, chemicals, and differing temperatures can lead to considerable wear in various other materials.

Furthermore, the lightweight nature of light weight aluminum, integrated with its corrosion resistance, adds to the longevity of industrial applications. This resilience minimizes the frequency of replacements and upkeep, ultimately supporting effective heat dissipation. Aluminum foundry spreadings are not just helpful for their thermal residential properties but also for their capacity to endure oxidative and corrosive obstacles, making certain peak efficiency in requiring setups.

Cost-Effectiveness and Energy Performance

The cost-effectiveness and energy efficiency of light weight aluminum foundry spreadings existing significant benefits for makers. By minimizing production prices and using energy savings, these castings stand for a sensible option for business aiming to maximize their operations. Additionally, the lasting financial investment worth connected with aluminum spreadings enhances their allure in an affordable market.

Lower Production Prices

While lots of sectors face rising manufacturing prices, light look at this web-site weight aluminum shops have actually progressively transformed to cutting-edge approaches to enhance cost-effectiveness and power performance. The use of aluminum for factory castings offers substantial advantages, as it calls for less energy to create contrasted to various other steels. Additionally, light weight aluminum's lightweight nature lowers transport prices and streamlines managing throughout making processes.

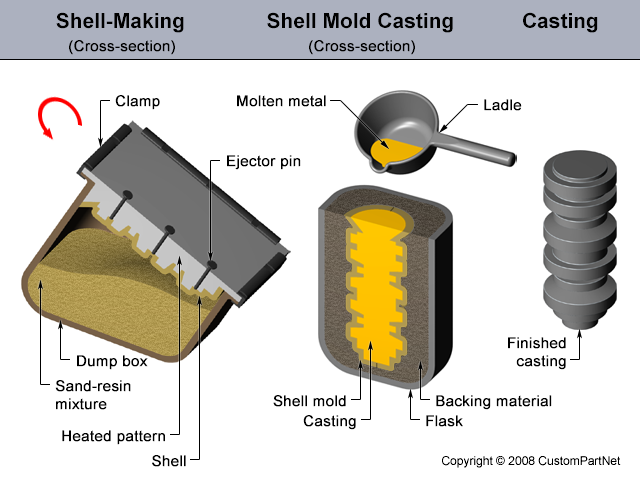

Using innovative casting methods, such as die casting and lost foam casting, can even more simplify manufacturing and decrease waste. Metal Casting. These modern approaches not only lead to faster turnaround times yet additionally permit the reliable use of raw materials. Aluminum factories are better placed to maintain affordable rates, inevitably benefiting sectors reliant on top notch castings for their procedures.

Energy Savings Conveniences

Energy cost savings represent a necessary benefit for aluminum factories, especially in the context of cost-effectiveness and power effectiveness. The lightweight nature of light weight aluminum permits for decreased energy consumption during manufacturing and transport procedures. In addition, light weight aluminum spreadings display remarkable thermal conductivity, making it possible for reliable warmth dissipation in commercial systems. This performance decreases the demand for substantial air conditioning systems, causing reduced power costs over time. Furthermore, the toughness and durability of aluminum castings lower the regularity of substitutes, adding to total energy savings in manufacturing cycles. By integrating light weight aluminum factory castings, industries can achieve significant decreases in energy expense while boosting functional efficiency, making it a strategic selection for cost-conscious producers seeking lasting solutions.

Long-Term Investment Value

Buying aluminum factory spreadings uses significant lasting worth, specifically pertaining to cost-effectiveness and power efficiency. These spreadings not just improve heat dissipation however also add to general system efficiency, resulting in lowered operational costs. The light-weight nature of aluminum enables much easier handling and transportation, decreasing logistical expenses. Furthermore, aluminum's longevity ensures a longer life expectancy, lowering the need for regular substitutes. Reliable warmth monitoring translates into reduced power consumption, which can considerably lower utility bills with time. In addition, business can benefit from boosted productivity as systems operate better. Ultimately, the first financial investment in light weight aluminum factory castings yields noteworthy returns, making them a wise option for industries aiming to maximize performance while controlling costs.

Applications of Aluminum Factory Castings in Market

Aluminum factory spreadings play an essential duty in different industrial applications as a result of their special residential properties, consisting of light-weight style and excellent thermal conductivity. These spreadings are widely made use of in the automobile industry for engine blocks, transmission cases, and heat exchangers, where reliable warmth dissipation is important for performance and safety and security. In the aerospace industry, light weight aluminum spreadings add to the decrease of airplane weight, consequently enhancing gas performance and general aircraft efficiency. In addition, in the electronic devices industry, light weight aluminum spreadings are employed in warmth sinks and enclosures, facilitating reliable thermal monitoring in tools. The adaptability of light weight aluminum foundry spreadings encompasses manufacturing equipment parts, where resilience and resistance to deterioration are essential. On the whole, the applications of aluminum shop spreadings extend several industries, highlighting their useful content significance in advancing technology and improving functional performance.

Frequently Asked Inquiries

Just How Do Aluminum Castings Contrast to Other Materials for Warmth Dissipation?

Light weight aluminum spreadings normally outperform several various other materials in heat dissipation as a result of their exceptional thermal conductivity. Contrasted to steel or plastic, light weight aluminum efficiently moves heat, making it a favored choice for commercial applications requiring effective thermal administration.

What Is the Lifespan of Light Weight Aluminum Foundry Castings in Industrial Applications?

The lifespan of light weight aluminum shop castings in industrial applications commonly ranges from 10 to thirty years, depending on ecological problems, upkeep, and operational anxieties, making them a long lasting choice for various commercial needs.

Just How Do Temperature Variations Affect Light Weight Aluminum Casting Performance?

Temperature variants can significantly impact light weight aluminum spreading efficiency, leading to thermal growth or tightening. These changes may create warping, tension fractures, or transformed mechanical buildings, ultimately affecting the resilience and integrity of the actors components in commercial applications.

Can Light Weight Aluminum Castings Be Recycled After Their Life Process?

Yes, light weight aluminum castings can be recycled important site after their life cycle. The reusing procedure retains the steel's homes, making it a sustainable option for various applications, consequently lowering waste and preserving resources in commercial operations.

What Surface Area Treatments Boost Aluminum's Warm Dissipation Features?

Surface therapies such as anodizing, painting with thermally conductive coatings, and using warm sinks considerably improve aluminum's heat dissipation homes. These methods improve area and thermal conductivity, maximizing efficiency in various commercial applications.

Aluminum foundry spreadings play a necessary function in boosting warmth dissipation within commercial systems. When used in shop castings, aluminum can be molded right into complex shapes that improve heat dissipation better. Style flexibility in warm management is a vital feature of aluminum castings that enables designers to enhance thermal efficiency in various applications. By leveraging innovative spreading techniques, engineers can make improvements the thermal homes of light weight aluminum spreadings to meet specific functional needs. Additionally, aluminum castings exhibit remarkable thermal conductivity, enabling effective warm dissipation in commercial systems.